For manufacturing businesses, smooth warehouse operations are critical to keeping production lines moving and customers happy. When stock is misplaced, orders are delayed, or materials aren’t where they need to be, the impact is immediate — production slows, costs rise, and customers start looking elsewhere.

A Warehouse Management System (WMS) gives manufacturers the tools to overcome these challenges by improving visibility, efficiency, and control across their operations.

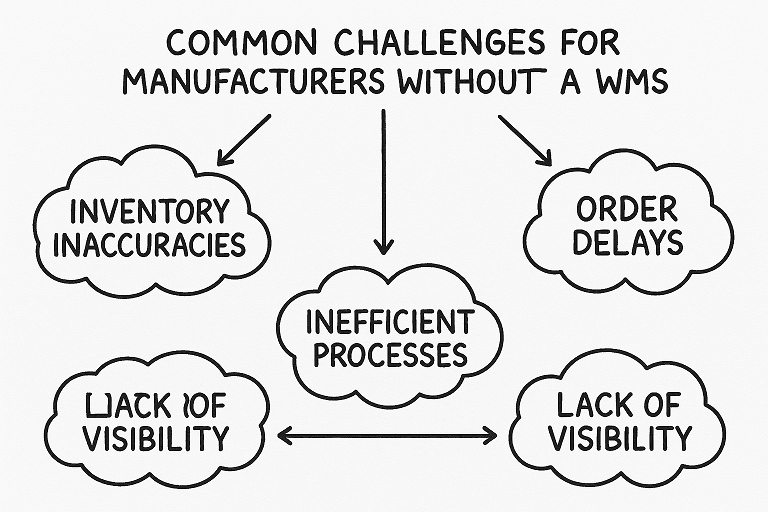

Common Challenges for Manufacturers Without a WMS

Manufacturing companies often face unique warehouse pressures that manual processes or basic systems can’t handle. Without a WMS, it’s common to see:

- Inventory inaccuracies – Miscounts or outdated spreadsheets can bring production to a halt if the right materials aren’t available.

- Production delays – Time is lost searching for raw materials, slowing down assembly lines and order fulfilment.

- High operating costs – Excess labour, poor space utilisation, and repeat errors all increase overhead.

- Limited visibility – Managers can’t see stock levels, order status, or warehouse performance in real time.

- Unhappy customers – Errors and delays impact reliability, damaging long-term relationships.

Benefits of a WMS for Manufacturing Businesses

By implementing a modern Warehouse Management System, manufacturers gain advantages that go far beyond stock control:

- Real-time inventory tracking – Always know what raw materials and finished goods are available to prevent costly shortages.

- Streamlined production support – Ensure materials are in the right place at the right time to keep lines running smoothly.

- Lower operating costs – Smarter storage, efficient picking, and reduced errors mean less wasted time and money.

- Scalable operations – A WMS grows with your business, supporting higher volumes and new production lines.

- Enhanced customer satisfaction – On-time, accurate deliveries strengthen trust and loyalty.

Why Manufacturers Need a WMS Today

The manufacturing sector is under increasing pressure to improve efficiency, reduce waste, and respond faster to customer demands. A WMS is no longer a ‘nice to have’ — it’s an essential tool for staying competitive. By giving your business visibility and control, a WMS helps turn your warehouse from a cost centre into a driver of growth.